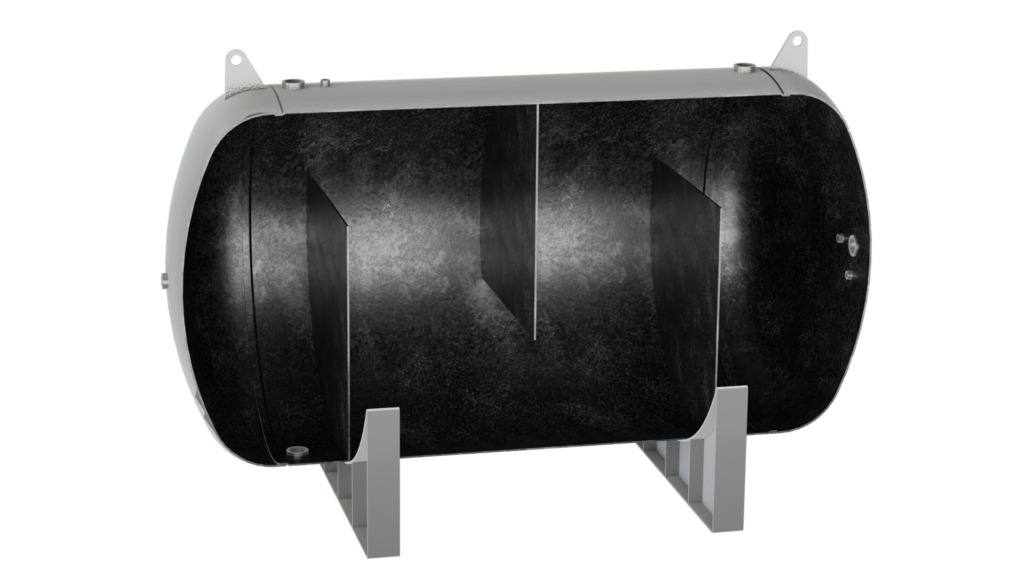

Buffer Tanks

Buffer tanks

Our buffer tanks add heating or cooling capacity to non-potable, closed-loop systems where the peak demand would otherwise exceed the ability of the system to satisfy it. They are found with low-mass boilers, geothermal systems, and large-scale environmental control systems.

Key Features and Benefits

As a chilled water buffer tank in an air conditioning or refrigeration system these tanks help satisfy demand when cooling loads are low by drawing from the chilled water they hold. This avoids the need for a full system start, which reduces equipment wear and overall energy consumption.

As a hot water buffer tank these tanks provide both thermal mass and thermal storage to a system. The thermal mass helps stabilize the water temperature while the thermal storage provides capacity during periods of low demand. This reduces the number of boiler starts and need for full system operation.

The reco buffer tanks are designed for storage capacities up to 2,000 gallons as standard and are available with storage capabilities up to 30,000 for custom orders. All buffer tanks are provided with an internal inlet deflector (CW) or flow partition (HW) and are available with a fully insulated and jacketed exterior. Installed in a system, the reco buffer tank reduces cycling, improves temperature control, and helps provide for a more even response to system demand.

reco buffer tank specifications and ratings

- MaterialsASTM SA-516-70 carbon steel tanks as standard

- SpecificationsDesigned to ASME B & PV Code, Section VIII, Division I

- Ratings150 PSIG max design pressure, 250°F max design temperature

- ConnectionsAll connections over 2½” are ANSI 150 lb. RFSO flanges

- ExteriorsSandblasted per SSPC-SP 6 and coated with a red oxide primer

- OrientationVertically mounted with a ring base or (4) support legs, Horizontally mounted with two support saddles